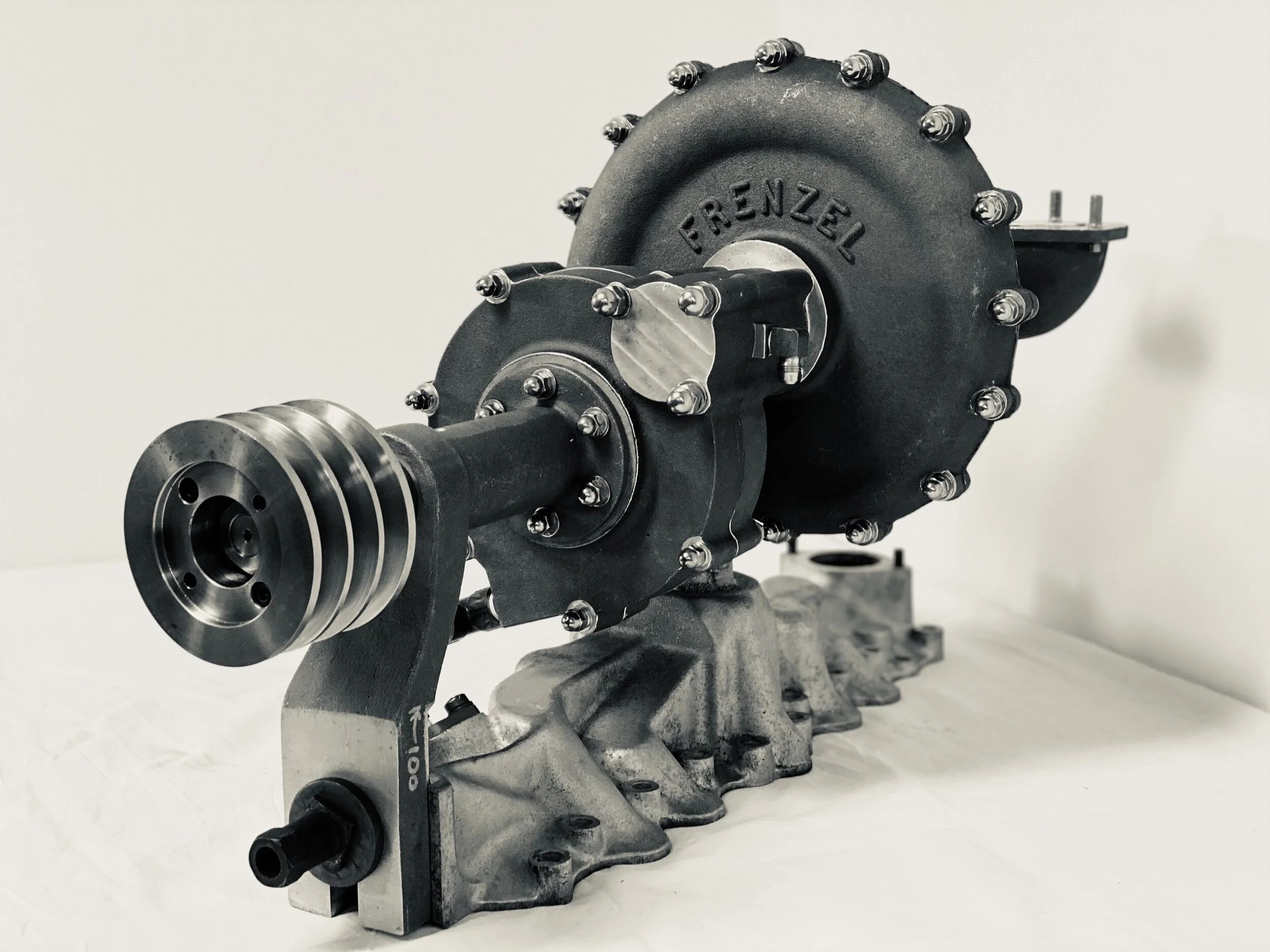

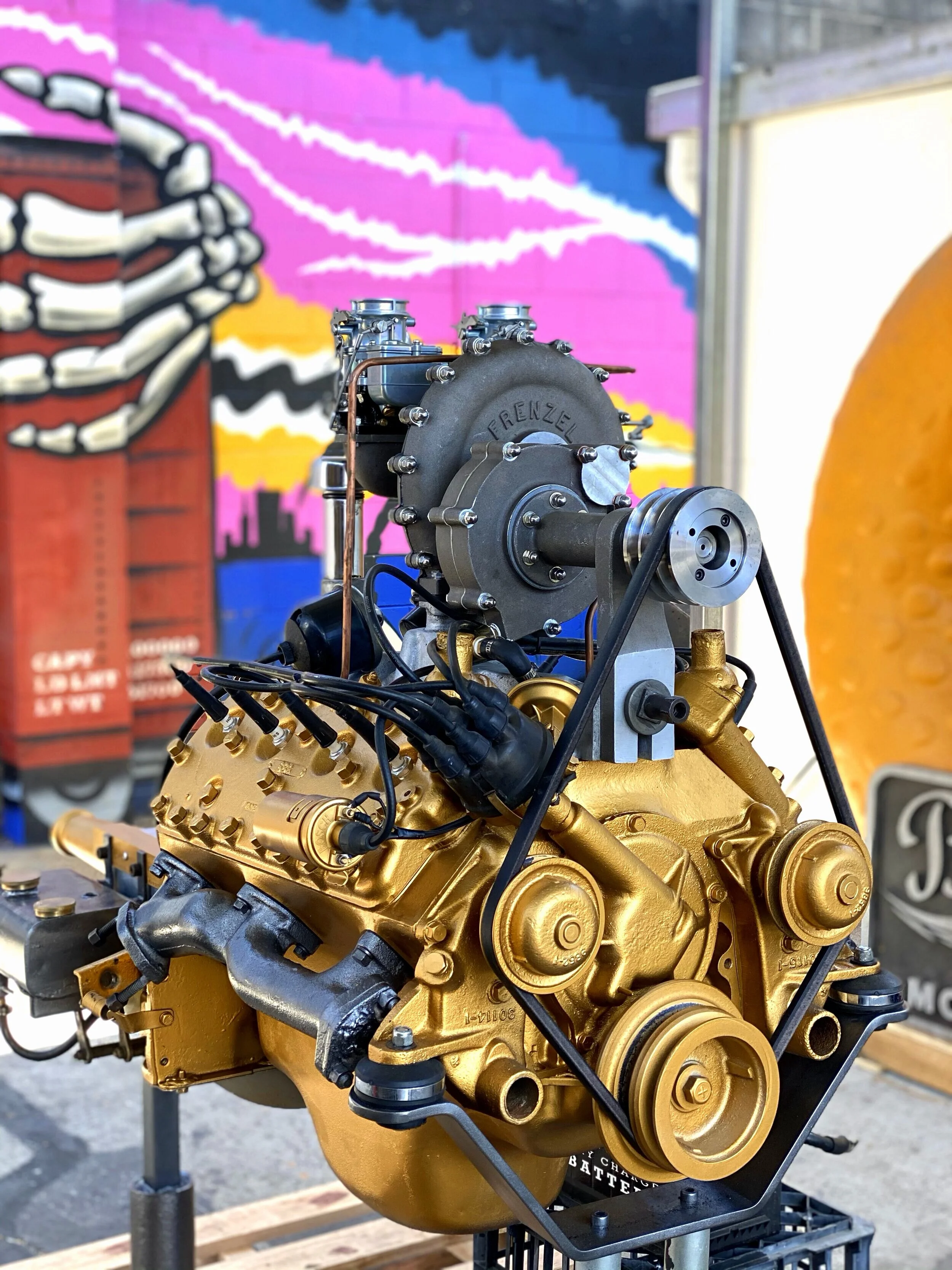

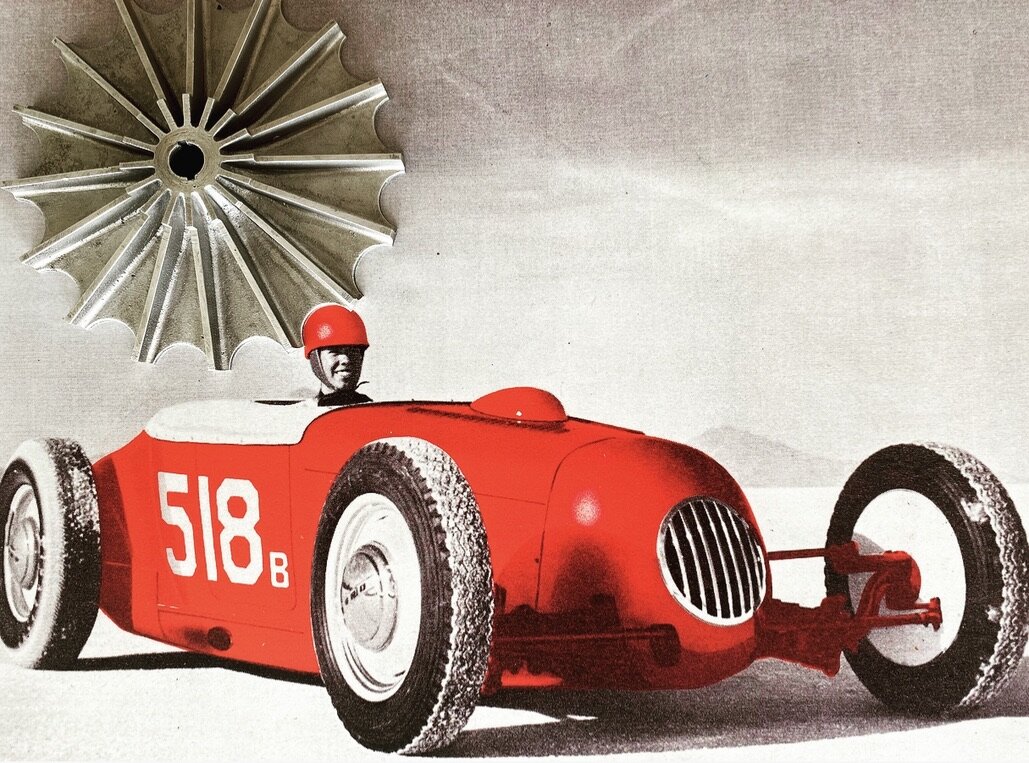

The New Frenzel.

Period correct wasn’t enough, we wanted perfection.

Labour of love doesn’t do the new Frenzel Supercharger justice. Labour of obsession more like. Period correct wasn’t enough, we wanted perfection. We’ve sweated every detail. After all we know what hotrodders are like. The subtle curve of a casting, the crease line of a forging, all telltale signs that something is correct. You can’t fool anyone with the precise angles and crispness of CAD. Time-old traditional techniques lead to the timeless feel we crave.

In the end we’re not accountants. We haven’t spreadsheeted the project to death predicting gross profit margins per second of manufacturing. This is a labour of love, if we come out even and end up with a blower on our cars we’ll be happy, if we manage to make a dollar you just know we’ll spend it on more hotrod parts.

But before we could even dream of getting to that stage we had to make the thing. And this is where the time comes in. Finding skilled artisans who can work in the field of pattern making, sandcasting and traditional machining isn’t impossible. But finding ones that will work on a limited run project while being dictated to by 2 anally retentive hotrodders is more difficult. And getting them to work to a deadline is even harder. After all perfection can’t be rushed no matter how much we prod and poke at it.